|

|

|

|

|

|

|

|

|

|

|

** TORX SCREWS | 6-LOBE SCREWS | 6LOBE SCREWS ** INCH SIZE CAP SCREWSTorx Inch Screws are characterized by the Torx Drive System and are generally made of low carbon steel or stainless steel. The material, low carbon steel, is primarily Grade 2. There are a minimum of seven head styles to choose from. The Inch Size Screws on this webpage are generally called Machine Screws. The major difference between Inch Size Machine Screws and Inch Size Cap Screws is that Cap Screws are generally made of alloy steel and are heat treated. Flat Head Cap Screws have a slightly larger head diameter than Flat Head Machine Screws. Hard to find items our specialty. Shopping is easy and delivery is fast. We have a huge inventory of these Torx drive screws and specialize in same day shipping. |

This website has many pages, but the first three pages make your search easier and quicker. The first page, in traditional website design, is called the HOME PAGE or sometimes referred to as the Landing Page. The second page is called the ABOUT PAGE and it is technical information for you, so you can make an intelligent selection of the screws that you need. If you already know the details of the screws that you need, you can go directly to page three, the SEARCH PAGE, to find what you need. You can go to the Search Page by clicking on any of the pictures above, or you can skip this page and go directly to the Search Page by clicking this Push Button that will take you there.

The diameter of the Torx Recess, shown in the first line drawing above, has been standardized and is usually designated in most specifications as dimension "A". This Torx Recess diameter "A" is the same for METRIC SIZE SCREWS as it is for INCH SIZE SCREWS. Because the word "Torx" has been copyrighted, this driving method is usually referred to as Tork Drive, 6-Lobe Drive, 6Lobe Drive, Six Lobe Drive and Star Drive, but the internationally acceptable designation, used worldwide, is "Hexalobular Internal Socket Drive" screws or the shortened version "Hexalobular Socket" screws. A table has been provided on this website that shows the essential elements of all 24 of the acceptable Hexalobular Socket Screws drive sizes including the diameter A in both inches and millimeters as well as the maximum torque range for each size including the torque range in both Newton - Meters and Pounds - Feet.

| TORX DRIVE RECESS DIAMETER SIZE EXPRESSED IN INCHES AND MILLIMETERS - MAXIMUM TORQUE RANGE EXPRESSED IN NEWTON-METERS AND POUNDS-FEET | ||||||

| CONVERT 0.73756 | ||||||

| TORX DRIVER | DIAMETER OF TORX DRIVE RECESS | MAXIMUM TORQUE RANGE | MAXIMUM TORQUE RANGE | |||

| SIZE | IN INCHES | IN MILLIMETERS | IN NEWTON-METERS | IN NEWTON-METERS | IN POUNDS-FOOT | IN POUNDS-FOOT |

| T-1 | 0.034 | 0.8636 | 0.02 | 0.03 | 0.014751 | 0.022127 |

| T-2 | 0.039 | 0.9906 | 0.07 | 0.09 | 0.051629 | 0.066380 |

| T-3 | 0.047 | 1.1938 | 0.14 | 0.18 | 0.103258 | 0.132761 |

| T-4 | 0.050 | 1.2700 | 0.22 | 0.28 | 0.162263 | 0.206517 |

| T-5 | 0.058 | 1.4732 | 0.43 | 0.51 | 0.317151 | 0.377631 |

| T-6 | 0.069 | 1.7526 | 0.75 | 0.90 | 0.553170 | 0.663804 |

| T-7 | 0.081 | 2.0574 | 1.40 | 1.70 | 1.032584 | 1.253852 |

| T-8 | 0.094 | 2.3876 | 2.20 | 2.60 | 1.622632 | 1.917656 |

| T-9 | 0.098 | 2.4892 | 2.80 | 3.40 | 2.065168 | 2.507704 |

| T-10 | 0.111 | 2.8194 | 3.70 | 4.50 | 2.728972 | 3.319020 |

| T-15 | 0.132 | 3.3528 | 6.40 | 7.70 | 4.720384 | 5.679212 |

| T-20 | 0.155 | 3.9370 | 10.50 | 12.70 | 7.744380 | 9.367012 |

| T-25 | 0.178 | 4.5212 | 15.90 | 19.00 | 11.727204 | 14.013640 |

| T-27 | 0.200 | 5.0800 | 22.50 | 26.90 | 16.595100 | 19.840364 |

| T-30 | 0.221 | 5.6134 | 31.10 | 37.40 | 22.938116 | 27.584744 |

| T-40 | 0.266 | 6.7564 | 54.10 | 65.10 | 39.901996 | 48.015156 |

| T-45 | 0.312 | 7.9248 | 86.00 | 103.20 | 63.430160 | 76.116192 |

| T-50 | 0.352 | 8.9408 | 132.00 | 158.00 | 97.357920 | 116.534480 |

| T-55 | 0.446 | 11.3284 | 218.00 | 256.00 | 160.788080 | 188.815360 |

| T-60 | 0.529 | 13.4366 | 379.00 | 445.00 | 279.535240 | 328.214200 |

| T-70 | 0.619 | 15.7226 | 630.00 | 700.00 | 464.662800 | 516.292000 |

| T-80 | 0.690 | 17.5260 | 943.00 | 1048.00 | 695.519080 | 772.962880 |

| T-90 | 0.784 | 19.9136 | 1334.00 | 1483.00 | 983.905040 | 1093.801480 |

| T-100 | 0.871 | 22.1234 | 1843.00 | 2048.00 | 1359.323080 | 1510.522880 |

This page of this website has been designed exclusively for Inch Size Machine Screws. Please remember that MACHINE SCREWS are characterized as made from non-heat treated steel & stainless steel and the most significant difference between MACHINE SCREWS and CAP SCREWS is illustrated by the head size differences in FLAT HEAD screws. If you refer to the Torx Drive sizes for the INCH SIZE screws on this web page and the Torx Drive head sizes for the same size screws on the INCH SIZE CAP SCREWS page, you will find that the Flat Head Machine Screw head diameter is slightly smaller than the same Flat Head Cap Screw and the DRIVE RECESS SIZE is also one size smaller. Generally, the Flat Head Machine Screws will withstand less torque than the equivalent Pan Head Screws because the Pan Head screw has much more steel or stainless steel in its head. Likewise the Flat Head Machine Screw will withstand less torque than the equivalent Flat Head Cap Screw because the Flat Head Cap Screw is heat treated and thus has a higher tensile strength than the equivalent Flat Head Machine Screw and therefore the Torx Driver size must be larger for the Flat Head Cap Screw when compared to the non-heat treated Flat Head Machine Screw to provide a higher torque (see table provided showing the maximum torque range for the two equivalent sized machine screws and cap screws). Generally, you will find that the Flat Head Cap Screw has a Torx Driver size that is one size larger than the equivalent Flat Head Machine Screw, except for the larger head size screws.

This Machine Screw Inch Size screws web page and its companion Cap Screw Inch Size screws web page shows all of the sizes that are readily available. Likewise, there is one more page that deals with Torx Drive Metric Machine Screws and another that deals with Torx Drive Metric Cap Screws. A table has been provided with each of the four pages showing the body size of each of the screws by their reference number as well as the decimal value of their body diameter. We have also provided a decimal value of the difference between the various sizes.

|

SCREW BODY SIZES BY NUMBER AND BY DECIMAL BODY SIZE FOR INCH SIZE SCREWS |

|||||||||||||||

|

BODY SIZE - NUMBER (#) |

#2 |

#3 |

#4 |

#5 |

#6 |

#7 |

#8 |

#9 |

#10 |

#12 |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

|

BODY SIZE - DECIMAL |

0.0860 | 0.0990 |

0.1120 |

0.1250 |

0.1380 |

0.1510 |

0.1640 |

0.1770 |

0.1900 |

0.2160 |

0.2500 |

0.3125 |

0.3750 |

0.4375 |

0.5000 |

|

DECIMAL DIFFERENT BETWEEN SIZES |

0.0130 |

0.0130 |

0.0130 |

0.0130 |

0.0130 |

0.0130 |

0.0130 |

0.0130 |

0.0130 |

0.0260 |

0.0625 |

0.0625 |

0.0625 |

0.0625 |

0.0625 |

Point contact causes stress risers to develop, which damages the driver bit and fastener recess. The Hex Socket Drive System has a 60 degree drive angle, which results in rounding off of the contact points of the hex socket drive system and damages both the fastener recess and the driver bit. This is called ROUNDING-OUT and everyone who uses Hex Socket Drive Screws has had the rounding-out problem and had to get out the old drill and try to remove the damaged screw. The Torx Socket Drive System has a 15 degree drive angle, which results in more torque that can be applied, less Torx Driver Bit wear and tear, and no damaged screws due to rounding-out. There have been studies that reported the DRIVE ANGLE alone makes the Torx Socket Drive System at least 5 times better that the equivalent Hex Socket Drive System. The original inventor of the Torx Socket Drive System (Camcar/Textron) was so thrilled about this major improvement over the Hex Socket Drive System that when they developed an improved version of the Torx Socket Drive System, they improved the drive angle to zero for the Torx Plus Socket Drive System, which means that additional torque can be applied and there will be less driver bit wear and reduced driver bit costs.

Camout is defined as the force upward on a screwdriver as the torsional force is increased in order to tighten the screw. The cruciform (Phillips) recess is at a 45 degree angle and the side walls of the Torx Recess is vertical, which results in virtually no upward force as the torsional force is increased. When camout occurs with a Phillips screwdriver, it usually means damages to the screwdriver bit as well as the drive recess of the screw. Camout can also damage the surrounding material around the screw. The two problems of driver fatigue due to having to apply such high pressure on the screwdriver and the large drive recess angle of the Phillips screwdriver is solved with the Torx Socket Drive System. Camout is eliminated with the use of Torx Drive Screws.

Other specific features of the Torx Socket Drive System includes, the recess completely encloses the drive bit, minimizing tool slippage and the damages and injuries it can cause, provides greater depth of lobe engagement between the driver and the Torx fastener, allows driving forces to spread over a broader surface, as opposed to the point of contact of many other drive systems, allows more efficient torque transfer, provides a better fit between the driver bit and the fastener recess, and extends the tool life.

This Tork Drive Flat Head is countersunk into the working surface and flat on top, so that the head rests flush with the working surface. These screws are used in areas where there is little or no tolerance for protrusions above the working surface. The countersink angle is 82 degrees for Unified Thread (Inch). Screw lengths are measured from the top of the head to the tip of the screw.

Differences Between Machine Screws and Cap Screws.

The countersink angle of the 82 degrees Flat Head screws has an international standard tolerance of plus or minus two degrees. The countersink can be as little as 80 degrees and as much as 84 degrees.

|

TORX DRIVER SIZE FOR INCH SIZE FLAT HEAD - 82 DEGREES MACHINE SCREWS AND CAP SCREWS |

|

BODY SIZE - NUMBER (#) |

#2 |

#3 |

#4 |

#5 |

#6 |

#7 |

#8 |

#9 |

#10 |

#12 |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

|

BODY SIZE - DECIMAL |

0.0860 |

0.0990 |

0.1120 |

0.1250 |

0.1380 |

0.1510 |

0.1640 |

0.1770 |

0.1900 |

0.2160 |

0.2500 |

0.3125 |

0.3750 |

0.4375 |

0.5000 |

|

MACHINE SCREWS - FLAT HEAD |

T-6 |

T-8 |

T-8 |

T-10 |

T-10 |

- |

T-15 |

- |

T-20 |

T-25 |

T-27 |

T-40 |

T-40 |

T-50 |

T-50 |

|

CAP SCREWS - FLAT HEAD |

T-8 |

T-8 |

T-10 |

T-10 |

T-15 |

- |

T-20 |

- |

T-25 |

T-27 |

T-30 |

T-40 |

T-45 |

T-50 |

T-50 |

Head height of a flat head screw is always referred to as a REFERENCE only, because it is not totally controllable since it varies due to the countersink angle tolerances and the head diameter tolerances. The countersink head angle of an 82 degree countersink screws is plus or minus 2 degrees which means that the angle may be as little as 80 degrees and as much as 84 degrees, with the NOMINAL countersink angle being 82 degrees. The diameter of the screw head depends upon the BODY SIZE of the screw and it can vary by plus or minus 0.010 from its nominal value.

This head is countersunk into the working surface and the flat on top so that the head rests flush with the working surface. The broader angle allows for a shallower countersink but with reduced bearing capacity due to reduced material. Screw lengths are measured from the top of the head to the tip of the screw.

|

TORX DRIVER SIZE FOR INCH SIZE FLAT HEAD - 100 DEGREES MACHINE SCREWS AND CAP SCREWS |

|||||||||||||||

|

BODY SIZE - NUMBER (#) |

#2 |

#3 |

#4 |

#5 |

#6 |

#7 |

#8 |

#9 |

#10 |

#12 |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

|

BODY SIZE - DECIMAL |

0.0860 |

0.0990 |

0.1120 |

0.1250 |

0.1380 |

0.1510 |

0.1640 |

0.1770 |

0.1900 |

0.2160 |

0.2500 |

0.3125 |

0.3750 |

0.4375 |

0.5000 |

|

MACHINE SCREWS - FLAT HEAD |

- | - |

- |

- |

T-10 |

- |

T-15 |

- |

T-20 |

- | T-27 |

T-40 |

T-45 | T-50 |

T-55 |

|

CAP SCREWS - FLAT HEAD |

- |

- |

- |

- |

T-15 |

- |

T-15 | - |

T-20 | - |

T-27 | T-40 |

T-45 |

T-50 |

T-55 |

Drive Size Comparisons Between 100 Degree Machine Screws and 100 Degree Cap Screws.

100 degree flat head machine screws are use extensively by the Military, Aerospace and Aircraft for thin metals and to save weight.

This head is countersunk into the working surface and flat on top so that the head rests flush with the working surface. The countersink is undercut part way down to reduce the head height. The undercut slightly reduces the bearing force of the head over traditional countersunk heads, but allows for more threads on shorter screws. Screw lengths are measured from the top of the head to the tip of the screw.

|

TORX DRIVER SIZE FOR INCH SIZE FLAT HEAD - 82 DEGREES - UNDERCUT - MACHINE SCREWS AND CAP SCREWS |

|||||||||||||||

|

BODY SIZE - NUMBER (#) |

#2 |

#3 |

#4 |

#5 |

#6 |

#7 |

#8 |

#9 |

#10 |

#12 |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

|

BODY SIZE - DECIMAL |

0.0860 |

0.0990 |

0.1120 |

0.1250 |

0.1380 |

0.1510 |

0.1640 |

0.1770 |

0.1900 |

0.2160 |

0.2500 |

0.3125 |

0.3750 |

0.4375 |

0.5000 |

|

MACHINE SCREWS - FLAT HEAD UNDERCUT |

T-6 |

T-8 |

T-8 |

T-10 |

T-10 |

- |

T-15 |

- |

T-20 |

T-25 |

T-27 |

T-40 |

T-40 |

T-50 |

T-50 |

|

CAP SCREWS - FLAT HEAD UNDERCUT |

T-8 |

T-8 |

T-10 |

T-10 |

T-15 |

- |

T-20 |

- |

T-25 |

T-27 |

T-30 |

T-40 |

T-45 |

T-50 |

T-50 |

Reason for undercut.

This head rests above the working surface with a slight rise on the sides and a sloped top. The extra material in the head allows for more torque on the drive, and more resistance on the bearing surface. Screw lengths are measured from under the head to the tip of the screw.

|

TORX DRIVER SIZE FOR INCH SIZE PAN HEAD MACHINE SCREWS AND CAP SCREWS |

|||||||||||||||

|

BODY SIZE - NUMBER (#) |

#2 |

#3 |

#4 |

#5 |

#6 |

#7 |

#8 |

#9 |

#10 |

#12 |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

|

BODY SIZE - DECIMAL |

0.0860 |

0.0990 |

0.1120 |

0.1250 |

0.1380 |

0.1510 |

0.1640 |

0.1770 |

0.1900 |

0.2160 |

0.2500 |

0.3125 |

0.3750 |

0.4375 |

0.5000 |

|

MACHINE SCREWS - PAN HEAD |

T-8 |

T-8 |

T-10 |

T-10 |

T-15 |

- |

T-20 | - |

T-25 | T-27 |

T-30 |

T-40 |

T-45 | T-50 |

T-55 |

|

CAP SCREWS - PAN HEAD |

T-8 |

T-8 |

T-10 |

T-10 |

T-15 |

- |

T-20 |

- |

T-25 |

T-27 |

T-30 |

T-40 |

T-45 |

T-50 |

T-55 |

This head rests above the working surface with raised sides and slopped top. The bearing surface is extended outward like a flat washer to help distribute bearing force when working with soft or fragile surfaces, or when dealing with oversized predrilled holes. The extra material in the head allows for more torque on the drive, and more resistance on the bearing surface. Screw lengths are measured from under the head to the tip of the screw.

|

TORX DRIVER SIZE FOR INCH SIZE PAN WASHER HEAD MACHINE SCREWS AND CAP SCREWS |

|||||||||||||||

|

BODY SIZE - NUMBER (#) |

#2 |

#3 |

#4 |

#5 |

#6 |

#7 |

#8 |

#9 |

#10 |

#12 |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

|

BODY SIZE - DECIMAL |

0.0860 |

0.0990 |

0.1120 |

0.1250 |

0.1380 |

0.1510 |

0.1640 |

0.1770 |

0.1900 |

0.2160 |

0.2500 |

0.3125 |

0.3750 |

0.4375 |

0.5000 |

|

MACHINE SCREWS - PAN WASHER HEAD |

T-8 | T-8 |

T-10 | T-10 |

T-15 |

- |

T-20 |

- |

T-25 |

T-27 |

T-30 |

-40 |

T-45 |

T-50 |

T-55 |

|

CAP SCREWS - PAN WASHER HEAD |

T-8 |

T-8 |

T-10 |

T-10 |

T-15 |

- |

T-20 |

- |

T-25 |

T-27 |

T-30 |

T-40 |

T-45 |

T-50 |

T-55 |

This head rests above the working surface with a broad bearing surface, little or no vertical rise, and a shallow slope to the top to provide an aesthetically pleasing appearance. The broad bearing surface reduces the need for flat washers to distribute bearing force when working with soft or fragile surfaces, or when dealing with oversized predrilled holes. Screw lengths are measured from under the head to the tip of the screw.

|

TORX DRIVER SIZE FOR INCH SIZE TRUSS HEAD MACHINE SCREWS |

|||||||||||||||

|

BODY SIZE - NUMBER (#) |

#2 |

#3 |

#4 |

#5 |

#6 |

#7 |

#8 |

#9 |

#10 |

#12 |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

|

BODY SIZE - DECIMAL |

0.0860 |

0.0990 |

0.1120 |

0.1250 |

0.1380 |

0.1510 |

0.1640 |

0.1770 |

0.1900 |

0.2160 |

0.2500 |

0.3125 |

0.3750 |

0.4375 |

0.5000 |

|

MACHINE SCREWS - TRUSS HEAD |

- | - |

- |

- |

T-10 |

- |

T-15 |

- |

T-20 |

T-25 |

T-27 |

T-40 |

T-45 | T-45 |

T-50 |

This head rests above the working surface with a narrow bearing surface and low vertical walls. The top may or may not have a slight rise or rounding on the edge. The side walls may or may not be knurled to allow for finger tightening. This head is used in applications where traditional full height socket heads may interfere with the function, but there is a need to maintain consistency in drive type. Screw lengths are measured from under the head to the tip of the screw.

|

TORX DRIVER SIZE FOR INCH SIZE HIGH ROUND SOCKET HEAD MACHINE SCREWS |

|||||||||||||||

|

BODY SIZE - NUMBER (#) |

#2 |

#3 |

#4 |

#5 |

#6 |

#7 |

#8 |

#9 |

#10 |

#12 |

1/4 |

5/16 |

3/8 |

7/16 |

1/2 |

|

BODY SIZE - DECIMAL |

0.0860 |

0.0990 |

0.1120 |

0.1250 |

0.1380 |

0.1510 |

0.1640 |

0.1770 |

0.1900 |

0.2160 |

0.2500 |

0.3125 |

0.3750 |

0.4375 |

0.5000 |

|

MACHINE SCREWS - LOW ROUND SOCKET HEAD |

T-6 |

T-6 |

T-8 |

T-8 | T-10 |

- |

T-15 |

- |

T-20 |

T-25 |

T-27 |

T-30 |

T-40 |

- |

T-50 |

|

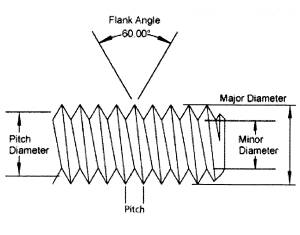

Thread diameters are really critical to the quality assurance department of any fastener organization. Fortunately, these diameters and their definitions have been standardized worldwide and are applicable whether the screws are INCH or METRIC. It is customary to refer to the PITCH of an INCH SIZE screw by TPI or threads per inch, whereas in the METRIC world, it is customary to refer to thread PITCH as the distance between threads in millimeters mm). Here is a table that clarifies these various THREAD DIAMETERS. |

|

Major Diameter | This is the diameter across the crest of the thread. It is easily checked with calipers. |

| Minor Diameter | This is the diameter across the root of the thread. The easiest way to heck this dimension is with an optical comparator. | |

| Pitch Diameter | This is the mid-point between the crest and the root of the thread. It is checked by using a pitch micrometer. | |

| Flank Angle | This is the angle made by the intersection of the two thread flanks. It is best checked with an optical comparator. | |

| Pitch | This is the distance between two consecutive thread crests. It is best checked with an optical comparator. |

We carry a full line of Torx® drive pan head and Torx® drive flat head machine screws and a full line of Torx® drive cap screws with flat heads, button heads and high round socket heads. If you just want more information about Torx® screws, we have provided a page on this web site where you can get this information. We also carry a full line of machine screw nuts, lock nuts, machine screw washers and lock washers. However, if you should need nuts, washers or other industrial fasteners, please go to the catalog index on the browse page and select the item of your choice.

You can shop and buy these industrial fasteners online. These industrial fasteners (sujetadores) come with Class 2A thread fit if they are plated and Class 3A thread fit if they are not plated. Most screws in our database are UNC Coarse Thread. We have a small number of UNF Fine Thread screws in stock but they are not listed in our database. You can call us toll free as shown on the home page if you want to check on the availability of UNF fasteners. The regular hex nut, lock nut, washer or lock washer that you might need, for the Torx® machine screws you buy, can be found on the machine screw nuts page or the machine screw washers page on our machine screws or cap screws web sites.

These fasteners are normally sold in quantities of 10, 100, 1,000 (or multiples thereof) but discounts are given for full carton orders. You may find that a carton order has the same or more pieces in the carton than an order for 100 or 1,000 and yet has a lower price because we are a volume supplier and reward the customer for volume business.

Shipping charges are calculated automatically while you are in the buying process. After you press the "Checkout" button a new screen will ask for shipping method, shipping address and payment method. If you are in California there will be an automatic sales tax added. We are unable to have contracts with every shipping company in the world. Therefore there will be an additional charge of $6.50 added to all orders when "freight collect" is specified by the customer. If you should want to try different shipping methods to get the one best suited for you, simply click the "Back" button on your browser, change the shipping method and click on "Continue". If you want to try still another shipping method, simply repeat this procedure or you can click on the button "see rates".

Back to Aaron's Torx® Drive Screws Home Page

Back to Aaron's General Store Home Page

|

HOW TO CONTACT US

Aaron's Torx Screws |

URL: http://www.Aarons6-LobeScrews.com

|

"TORX® is a registered trademark of Acument Intellectual Properties, LLC" |

Copyright © 1999 - 2016 Aaron's General Store.com

|

|